The Referee Level Particle Standard (RLPS™) Set,

which is sometimes referred to as a "Challenge Set", is available for the training of inspectors and determination of the

human visual inspector baseline using the appropriate manual

inspection booth. The Basic

RLPS™ set provides

samples seeded with a single particle of a measured specific size.

The seed materials vary in density to demonstrate to the inspector different

movement characteristics in container. The seed materials include but are

not limited to: spherical shape (stainless steel, borosilicate glass, and

polystyrene), irregular shape (glass shards, glass lamina, stainless steel

shavings, aluminum shavings, Teflon®, nylon fiber, cellulose fiber,

HDPE, Blue Gown material, filter materials, and many more materials that may be

found in the manufacturing or filling area. The RLPS™ Sets are

manufactured in Standard and Extended sets to best meet your requirements.

The RLPS™ Sets are available in three configurations: 1) a set which is manufactured using Customer Supplied Materials, 2) a set manufactured using a combination of Phoenix Imaging and Customer Supplied Materials, and 3) a set manufactured using only Phoenix Imaging Supplied Materials. Phoenix Imaging only use Schott Type 1 Tubing Vials for preparation of the RLPS™ sets when using our materials. Phoenix Imaging also offers a "Rapid Delivery" RLPS™ set which reduces the delivery time by pre-leaching the glass vials. The vial preparation period is one of the most critical steps and the leaching process is an important part of the operation.

The

RLPS™ samples are produced using customer specified containers, stoppers,

seals and fluid fill level. The standard

spherical particle sizes range from 50µm to

800µm in

diameter. The irregular shape particles can range from <100

µm to >1500 µm in proximal length. The RLPS™ set is designed to train,

evaluate the detection

capability of individual inspectors and the qualification of

inspectors. Following the training mode, the

RLPS™ set can be used to generate a calibration curve

or the Human Response Curve (HRC). The

curve

relates particle size to particle rejection probability at a

given light intensity in the inspection volume. The use of the

calibration curve provides an economically effective alternative to the

re-determination of the rejection probability of each particle in the sampled

container set. Without the calibration curve the rejection probability of each

container in the sampled container set must be independently generated.

This

would entail multiple inspections of each container in the sample set to achieve

0.95% confidence results.

The RLPS™ - Basic set includes stainless steel,

glass and polystyrene spheres ranging in

size from 40µm to 800µm along with

irregular shaped particles of various materials. The RLPS™ Extended set also includes

additional fibers, floaters, and

shards of materials found in the manufacturing environment as sample contaminating particles for training purposes.

The

standard solution used in the

fabrication of the RLPS™ set is Water For Injection (WFI) and is therefore clear in appearance.

The

test samples are prepared with particles of known sizes that are NIST traceable.

Phoenix Imaging has developed a high resolution optical

measurement system that is capable of measuring the particle size to ±1µm.

The RLPS™ Extended set is not required but is

the most popular set and is recommended

for most customers. Additional containers may be purchased with a wide

selection of contaminating particle upon request. We can also add

discoloration, turbidity and fluid viscosity changes to the samples set if

requested for a nominal up charge.

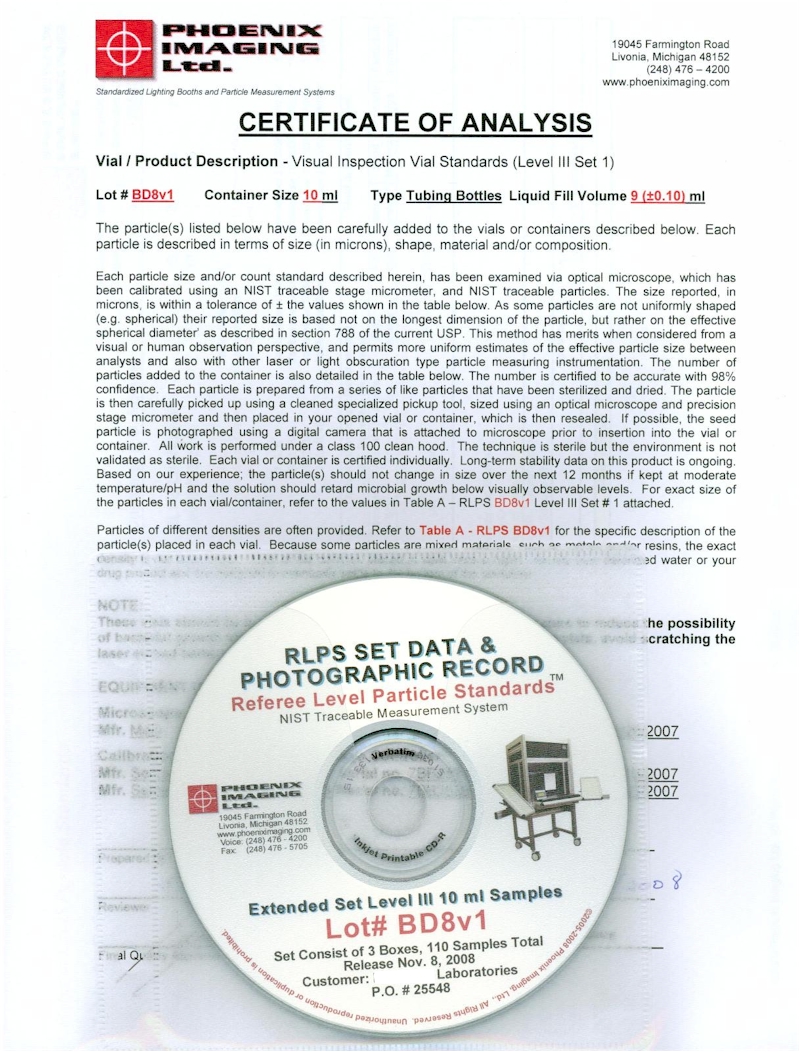

Since the Referee Level Particle Standards are used for training and inspection qualifications the set must meet the strictest requirements for clarity and particle size determination. The containers provided by the customer are requested to be cleaned and depyrogenated as if they were to be used in production. We rewash the containers and stoppers in the preparation process. The containers are examined very carefully to insure that they free of any contamination prior to the seeding operation. We have found that container quality has a considerable influence on the preparation time. An important part of the preparation is to insure that all of the trace elements have been removed from the container interior walls. Each container is sealed with a closure that is laser marked with unique Lot/Serial number that identifies the actual content of the container. The customer is supplied with Certificate of Analysis (COA) that describes the container, its contents and the seed particle material and seed particle size (see sample sheet below).

Each RLPS™ set is seeded with particles that are populated from very small (40-50 µm) to very large (800 - 1100 µm). The largest percentage of particles is concentrated is near the visible limit of human inspectors at 500 foot-candles of illumination for container of a particular size. Small containers (1 ml) shift the center of the particle distribution toward small particle sizes (Level I) and larger containers (500 - 1000 ml) shift the center of the particle distribution to large particle sizes (Level VI). The container material also has an influence on which Level particle standards should be used for seeding. Each individual seed sample is examined for shape and measured precisely to ±1 µm, it is then photographed for inclusion into your records prior to seeding. You are supplied with all documentation and photographs on a CD-ROM included with samples. Phoenix Imaging offers RLPS™ sets in seven different levels. Each level represents the size of the particles in the center of the distribution. The higher the level number the larger the particle size at the center of the distribution. Level III is considered normal with the 100µm spherical particles in the center of the distribution when using a 5 ml clear glass vial and 500 foot-candles of light in the inspection volume of the manual inspection booth. For example, if the container were to increases in volume, or change from clear to amber or the light intensity used for the inspection were decreased, then the center of spherical particle distribution would need to increase, i.e. Higher Level Number. The purpose of the RLPS™ set to produce a Human Response Curve (HRC) with the inflection point at the 70% Probability of Rejection (PR).

Note: The RLPS sets only include stainless steel and borosilicate glass spherical particles. Spherical particles are required so that particle orientation will not influence the perceived size of particle when determining the efficiency of each operator in the human baseline determination study.

65 vials total (16 seeded, 49 clean)

Stainless Steel Spheres sizes range from 50µm - 800µm

Glass Spheres (transparent) sizes range from 70µm - 500µm

100 vials total (36 seeded, 64 clean)

Stainless Steel Spheres sizes range from 50µm - 800µm

Glass Spheres (transparent) sizes range from 70µm - 1100µm

Glass Shards (transparent) sizes range from 500µm - 1,500µm

Nylon Fibers (Black) sizes 1, 2, & 3 mm (Other sizes upon request)

LDPE (white irregular) sizes 200 - 300 µm proximal length

Polystyrene (Translucent spherical) sizes 100 - 500 µm diameters

150 vials total (50 seeded, 100 clean)

Stainless Steel Spheres sizes range from 50µm - 800µm

Glass Spheres (transparent) sizes range from 70µm - 1100µm

Glass Shards (transparent) sizes range from 100µm - 1,500µm

Nylon Fibers (Black) sizes 250µm, 500µm, 750µm, 1, 2, & 3 mm (Other sizes upon request)

LDPE (white irregular) sizes 200 - 300 µm proximal length

Polystyrene (Translucent spherical) sizes 100 - 500 µm diameters

Aluminum Fragment (irregular) sizes 200µm - 1 mm proximal length

Stainless Steel Fragment (irregular) sizes 200µm - 1 mm proximal length

Hair (Black or Blonde) filament size 300µm - 1 mm proximal length

The Standard or Extended Sets may be customized with Additional Samples requested by the customer.

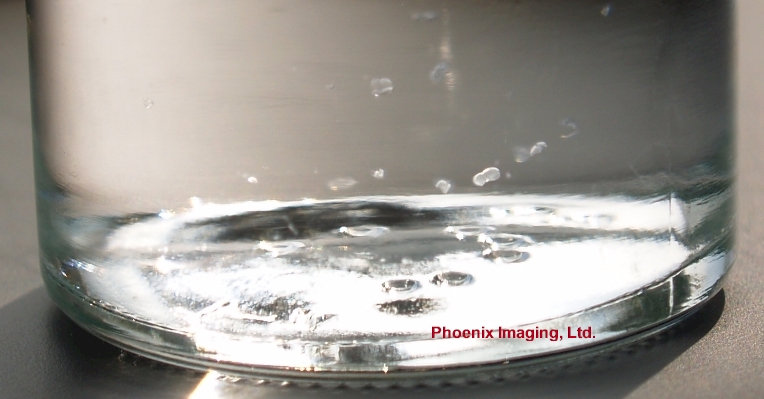

Typical additional seeding materials include: gown material, Teflon, LDPE, Viton, aluminum shards, cellulose fibers, hair, Lamina (see image below right), etc.... The customer may also request that the containers have altered viscosity, color or turbidity (see sample image below left). We will attempt to manufacture these samples to closely match examples provided by the customer or of our own design. The cost of the Custom samples is dependent on the seeding material, the composition of the solution and the container size. Please contact the office for additional information.

Turbidity

Turbidity

Lamina

Lamina

The RLPS™ sets are provided with photographs of the actual seeds used in the samples. The report includes the actual seed sizes as measured with an NIST traceable translation stage with special high power microscope and image processing system. All containers are laser marked on the aluminum closure (vials) with a indelible 2-D code and equivalent human readable code. All documentation is provided in written form (with exception of the photographs) and on a CDROM or DVD. A example of a Certification of Analysis is shown below along with a CDROM record.

Sample "Certificate of Analysis" supplied with each RLPS™ set.