|

Products

and

Solutions

for:

| |

Phoenix Imaging offers

ShaPix® 3-D Surface

Analysis System

Phoenix Imaging now represents the latest technology in

Digital Holographic High-Definition

Defect Detection & Metrology Systems

ShaPix®

technology is used to precisely measure the surface topology (depth (z-axis)

measurements) on flat structures. The primary use is to determine flatness

over large area such as the deck face on engine blocks, heads, transmission

plates, engine components where seal integrity is critical.

Imagine using millions of laser micrometers to examine a

surface and then map the information so that it can be interrupted visually.

The use of millions of laser micrometers would not only be cost prohibitive but

impractical to implement. The ShaPix® technology provides a

feasible alternative to very slow contact methodologies with better accuracy.

This exciting new technology has required millions of dollars of investment and

many man-year's of development to complete. This is not an

inexpensive vision solution with basic solution costing >$250K.

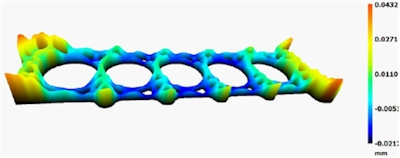

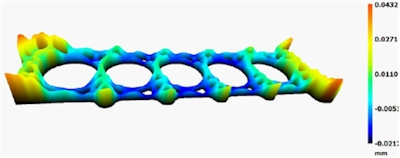

Pseudo-color image of ShaPix data map of engine block

deckface.

However, the result is impressive and it provides insight

into industrial applications that have not been possible to date. Contact

us and we will be happy to discuss the potential of your application. For

additional information see the following link

ShaPix® Specifications.

The baseline

ShaPix®

Surface Analysis System includes two

major units, the sensor head unit and the electronics unit. A variety of sensor

head bases and peripheral options are also available. The Baseline systems

include high-definition surface global and zone flatness and waviness surface

metrology functions as well as multi-view surface stitching. Lateral defect

detection and measurement accuracy is specified for the specific

ShaPix Surface Analysis System

that is ordered (request specifications tables). The

complexity of the inspection system requires that all desired defect detection

and measurement functionality must be ordered at the time of the original system

order and can not be field retrofit. Phoenix Imaging is your

ShaPix®

Surface Analysis System representative

for applications involved in Aerospace, Automotive, and Fuel Cell Technologies.

|

Performance Specifications |

|

|

|

Maximum data points per view |

|

up to more than 4 million |

|

Maximum views combinable per

surface |

|

unlimited |

|

Measurement time per view |

|

1 minute or less/per surface view |

|

Working depth of measurement

(Z) |

|

1 centimeter or more |

|

Working Volume

(Part/Assembly Size) Accommodated |

|

up to 750mm x 750mm x 660 mm |

|

Basic height (Z)

repeatability |

|

< 1 micron |

|

Basic height (Z) accuracy |

|

< +/- 1 micron |

|

|

|

|

|

Lateral (X-Y) field of view (various models) |

|

300 mm x 300mm, 200 mm x 200 mm, |

|

|

|

100 mm x 100 mm, or 50 mm x

50 mm |

|

|

|

combinable into any larger

areas |

|

Lateral (X-Y) accuracy |

|

|

|

Extended feature presence

location, size |

|

+/- 15, 8, 5 or 3 microns ( 3 sigma) |

|

(e.g., holes, edges relative

to datums) for feature area |

|

> 1 mm2, 0.5

mm2,

0.3 mm2

or 01.mm2 |

|

Point feature detection

(e.g., porosity) for 95% Pd |

|

1 mm2, 0.5 mm2,

0.3 mm2,

or 0.2 mm2 |

|

|

|

|

|

|

|

|

|

Environmental Specifications |

|

|

|

Ambient operating

temperature |

|

15-35 degrees C |

|

Humidity |

|

5-95% relative, non-condensing |

|

Supply voltage |

|

115V or 230V AC +/- 5%; |

|

|

|

50Hz or 60Hz +/- 2% |

Note:

Micron-level defect detection and metrology using any methods or devices

whatsoever must

take into

account the various static and dynamic physical effects which inherently affect

the actual

dimensions and

observability of the parts and assemblies that are to be processed. These

include

vibration, shock

and differential thermal effects.

|