|

Products

and

Solutions

for:

| |

Vector Correlation - A Patented Approach

The vector correlation technique, as applied to

optical character recognition, was patented by Phoenix Imaging as a viable approach to

reading dot matrix characters. The technology was developed as a method to read

indent markings on metal components and is offered under the name of MTx™ , which is

short for Material Tracking. The character recognition technology used in the

MTx™ Package is protected under U.S. Patent number 5,214,719 and 5,317,652 are owned

by Phoenix Imaging. The reading of indent marks on a metal component is among the

most difficult applications in the machine vision industry. Having approached the

task of generating an OCR system for identification of indent mark symbols made most other

OCR applications appear simple.

Definition

Vector correlation refers to a technique in which symbols are

identified using a set of points in two dimensional space.

Methodology

The concept behind the vector correlation approach is a rather simple.

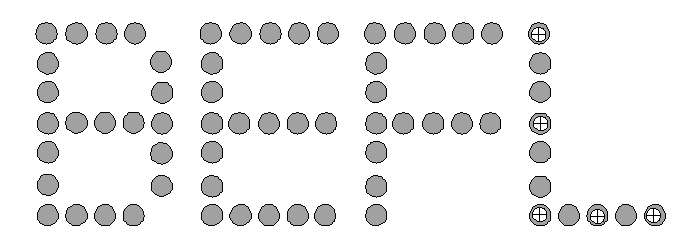

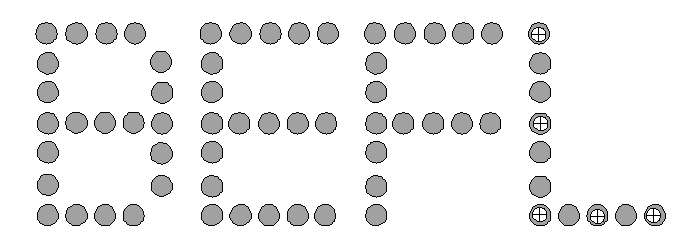

Consider the dot matrix symbol in Figure 6 below. The symbol "E" is generated

with a 5 x 7 dot matrix, in which the points do not touch each other. The ideal position

for the vector correlation points to identify this symbol would be centered in each point

generated by the dot matrix marking system. One of the points is selected as the home

position or origin of the vector correlation pattern. The x-y displacement from the origin

to each of the other correlation points defines a vector, thus the term vector

correlation.

Dot matrix character and a full set of vector correlation points

The vector correlation technique generates a separate

set of correlation vectors for each symbol taught. We can threshold an image so that

the desired symbols appear as binary information in the foreground. That is the

foreground information is considered to have a value of 1 and the background information

is considered to have a value of 0. The vector correlation points can be taught in

either the foreground or the background. If the symbol appears in the foreground the

points that match positions within the symbol are referred to as positive points. If

one selects the position of the positive points correctly it is usually possible to

uniquely identify the symbol. However, if several symbols have similar shapes it may

be beneficial to include negative vector correlation points. The figure above illustrates

the proper training of positive and negative vector correlation points for the symbol

"E". Notice that it is not necessary to use all of the points that

comprise a dot matrix symbol for training the vector correlation points. In fact,

the training of most symbols require less than half the number of points that are used to

generate the symbol.

The best location for the vector correlation

points depends on the symbol. However, a few general rules can be applied for the

identification of most symbols:

- The home position is typically selected at the center of the symbol;

- At a minimum, vector correlation points should be selected at the perimeter positions of

the symbol;

- Features common to multiple symbols usually do not contribute to uniqueness of the

symbol;

- The number of negative points should be kept to a minimum when applying the technology

to optical character recognition.

The Phoenix Imaging MTx™ System also allows for missing hits.

A "hit" is considered a match of a vector correlation point (either

positive or negative) with the foreground image. The percentage of hits can be

selected to allow one or more vector correlation points to be absent from the data and

still record the symbol correlation as a match. The system allows for the

independent percentage adjustment of positive and negative correlation points.

Distinct Advantages of the Technology

There are several advantages to this technology

over the other optical character recognition approaches previously mentioned. The vector

correlation approach is literally a "perfect match" for reading dot matrix

characters. When the vector correlation points are taught at the center of each dot used

to generate the dot matrix symbol, the position of the dot can vary by ½ its diameter and

still be found. This is very important given the fact that markings generated with dot

matrix marking systems tend to drift slightly. The second advantage is that dot matrix

symbols are composed of discrete dots and the technology does not have to "knit"

the dots together in order to isolate a match. The third advantage is that missing or

extra dots will not significantly affect the reading ability of the technology. This is

especially true when the movement of dots causes displacements between the symbol

segments.

Additional tools to improve recognition accuracy

Background Normalization

All machine vision applications require a certain level of image

quality in order to perform the application reliably. Several tools have been implement in

MTx™ System to broaden the "acceptable" image quality level. Variations in

background often make it difficult to extract the desired information. We have selected

the "Background Normalization" procedure as a preferred method whenever

possible. The "background normalization" procedure smoothes the background

features using grayscale morphology functions, "maximum", "minimum"

and "subtraction". The sequence of operators depends on whether the information

that we wish to extract is dark or light with respect to the background. The grayscale

normalization performs a "max.", "min.", "sub." sequence if

the symbols are dark with respect to the background. If the symbols are light with respect

to the background the grayscale normalization uses a "min.", "max.",

"sub." sequence. The kernel size of the "max." and "min."

operators should be programmable. The kernel size will vary based on the size of the dot

matrix marks. Regardless of the sequence used, the background normalization procedure will

yield a "relative" contrast image that will emphasis the marking. The background

normalization procedure is usually not implemented on frame grabber type image processing

equipment. The procedure is requires a considerable amount of computation and would slow

the system to a crawl. The background normalization procedure is best handled on equipment

designed to perform high speed grayscale morphology operations.

Precedence

The concept of precedence is an important part of the vector

correlation technique. During the early development of the technology, circa 1988, the

technology only implemented positive correlation points. With the use of positive

correlation points it is possible to match one symbol within another symbol. Consider

Figure 10 below, the dot matrix symbols "B", "E", "F", and

"L". The symbols are arranged in the order of complexity from right to left,

right being simplest and the left being the most complex. A match for the symbol

"L" might be found in the symbols "E" and possibly "B" in

the bottom right correlation point in moved to the left slightly. The same analogous

situation is true of the symbol "F", a match for it can be found in the

"E" and possibly the "B". However, the inverse in not true, the symbol

"F" will not be found in the symbol "L", nor would the "E"

be found in the "F". Therefore, we can arrange the symbol in an increasing order

of complexity. This table of complexity, arranged from the most complex to the least

complex in referred to as the "Precedence" table. The position of a symbol in

the Precedence table determines its "Precedence Value", the higher the value the

more complex the symbol. The Precedence Value is then assigned to the "Correlation

Number" for a particular symbol.

Order of symbol complexity

Symbol Spacing

Another Use important concept is that of symbol

spacing. Symbol spacing is defined as the distance in pixels from one symbol to the next

symbol. The measurement point should be consistent, either the leading edge of the symbol

or the center of the symbol. The concept of symbol spacing is used to identify whether

"white space" is present within a string of symbols. The MTx™ system also

uses the symbol spacing to determine the allowable position of symbols within the image

area. If the symbol spacing is selected at a distance of 30 pixels, only a single symbol

is allowed to be identified within that 30 pixel region. The spacing is determined by

locating the first symbol and adding symbol spacing incrementally from that position. If

for some reason more than one symbol is located within a given symbol spacing, the symbol

with the highest Precedence Value is selected.

Image Rotation

In many industrial applications the symbols are

presented to the sensor in random orientations, e.g. the axis of the symbols is not

aligned in a predefined orientation. Phoenix Imaging has found that the orientation of the

principle axis of the symbol string is good method for orientation determination. This

assumes that the symbol string is greater than two symbols in length and that a major axis

can be isolated. Using morphological techniques the principle axis of the symbol string

can be determined and then a rotation offset from a "normal" image orientation

can be applied to rotate the image. Electronic image rotation has be applied for many

years and provides the fastest for presentation of the symbol strings. Phoenix Imaging

prefers to rotate the entire image rather than small sections of the image because it

generates less "stair-step" effect. This technology is useful for identification

of symbols that a presented to the sensor in random orientations, e.g. markings on the

bottom of containers or non-oriented components on a conveyor.

OCR vs. OCV

The conceptual difference between OCR and OCV can now be

explained. In OCR applications the symbols are known but the order in which they appear in

the string is not known. In OCV applications, both the symbols and the order in which they

should appear are known.

The OCR application is more difficult to obtain reliable results than

the OCV application. The increased difficulty arises out of the uncertainty of which

symbols are allowed in which positions within the string. If the position of symbols

within the string can be assigned to particular symbol sets the read accuracy can be

improved. Often the customer has a defined arrangement of symbols within the symbol string

to identified. The MTx™ system allows the user to assign the type of symbol that can

be found in particular positions within the string. For example, the customer product code

will only allow an alphabetic symbol in the first position followed by seven numeric

symbols. In this case the allowable symbol set for the first position is includes 26

symbols. The next seven positions are then limited to symbol set of 10 symbols.

OCV applications are generally concerned with the quality of the

marking. The image processing system does not have to "read" the information in

order to determine which component is present. The system is informed of the symbols

present prior to starting the inspection. It is common for OCV applications to train

"acceptable" printed symbols as "references". The reference symbols

are then compare them to each new test image. The vector correlation technique can be used

as a method of precise symbol location and then the "reference" symbol is

compared to the test image. This technique will provide precise locations of extra or

missing print regions between the "reference" and "test" symbols.

The OCV application is easier to perform than an equivalent OCR

application for several reasons:

- The symbols are known prior to the inspection process;

- The position of each symbol is known prior to the inspection process; and

- In certain cases the symbols can be combined into a single symbol and its presence or

absence can be determined during the inspection process.

The MTx™ system allows the user to learn a symbol string as a

single set of vector correlation points. This technique is useful when the customer

does not care about the quality of the marking, but simply wants to insure that the mark

it is present.

|